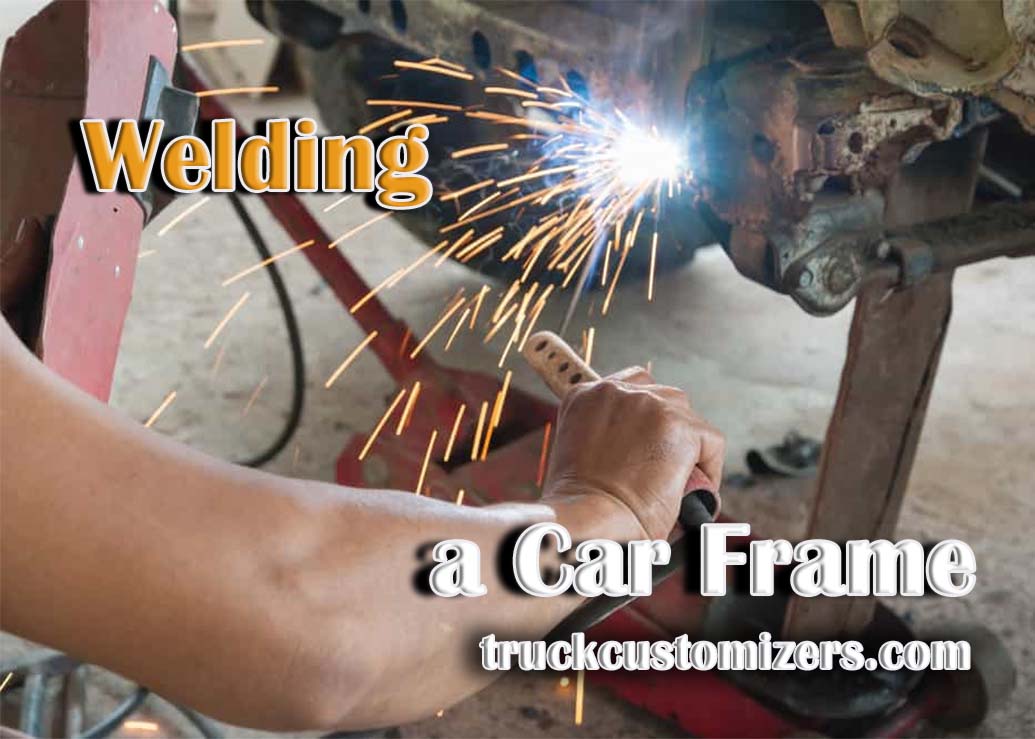

Welding is a great way to repair your car frame and give it a customized look. It takes some skill, however, so if you don’t have experience with welding it’s important that you familiarize yourself with the process before you attempt to weld your frame yourself. In this guide, we’ll take you through all the steps of welding a car frame, from prepping it to making sure your welds meet code requirements when you’re finished.

Prepping the Frame for Welding

The first step in welding your car frame is prepping it for the job. First things first – take off any rust and paint that’s on the surface of your frame using an angle grinder or sandpaper. This will ensure better adhesion between metals when you’re welding them together later on in the process. You’ll also need to gain access points so you can weld different parts of your frame together. This means drilling holes into the frame itself so you can fit your welding materials and tools through.

The Importance of Cleanliness and Proper Safety Gear

When prepping your frame for welding, it’s important to keep it as clean as possible. Any oils, dirt or debris on the surface of your frame can interfere with the welds later on. It’s also essential that you wear all necessary safety gear when prepping your car frame for welding – including a face mask, gloves and protective clothing.

Selecting Materials for Your Frame Welds

The type of metal you choose for your frame welds will play a big role in how strong they are, so make sure you select an appropriate metal for the job. The most common types of metals used in car frames are steel and aluminum – but other metals like stainless steel can be used too. You’ll also need to select a rod or wire that is suitable for the type of metal you’re using – such as mild steel rod or flux-cored wire.

Gaining Familiarity with Different Types of Welds

Before attempting to weld your car frame, it’s important to familiarize yourself with different types of welding. The three most common types are MIG, stick and TIG welding, and each has its own set of advantages and disadvantages. MIG is the most popular type of welding for car frames as it produces strong welds quickly and is relatively easy to learn. Stick welding is another option – but it takes more skill to master and can be messy since you have to use flux to keep the joint cool while welding. And lastly, TIG welding can produce high-quality welds with good aesthetics, but it’s also one of the more difficult methods to learn.

Executing Your Frame Welds

Once you’ve chosen your materials and mastered your welder technique, it’s time to actually start executing your frame welds. Depending on what kind of joint connection you need for your car frame (butt joint, lap joint or corner connection), there are a few different techniques you should use when executing your welds. For butt joints (where two pieces of metal butt up against each other), make sure that both surfaces are even before starting to weld so that your weld won’t have any weak points in it. For lap joints (where one piece overlaps another), make sure that the overlapping piece is flush with the other before beginning to weld. And for corner joints (where two pieces of metal meet at a corner), you’ll need to use a jig or fixture so your weld is as strong as possible.

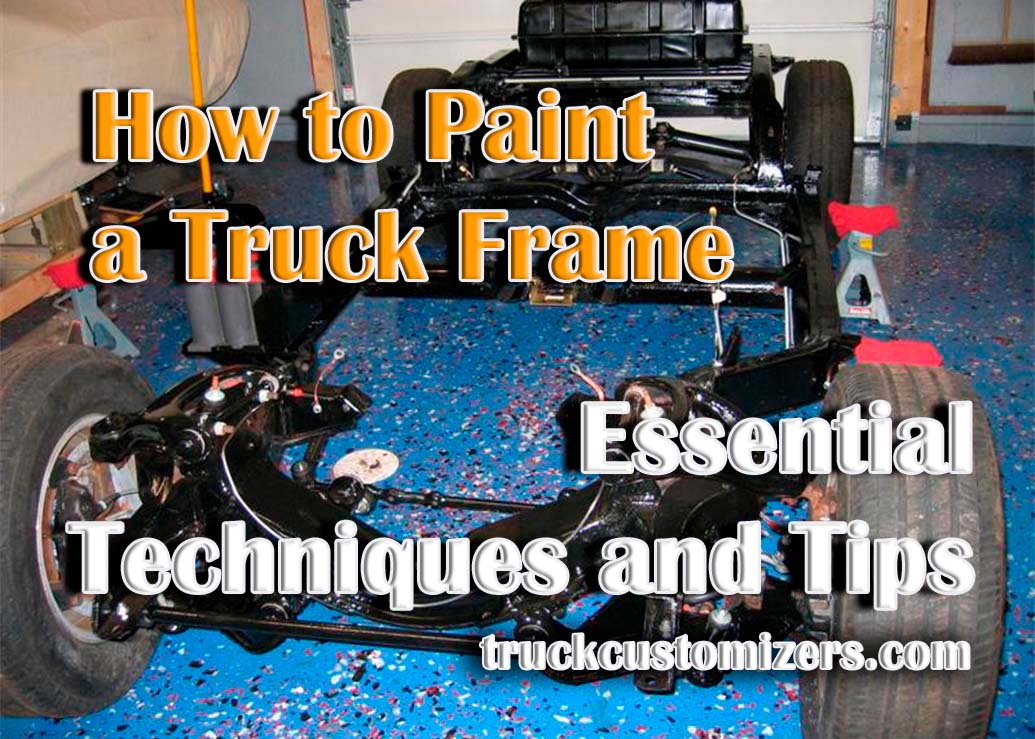

Finishing and Cleaning Up

Once you’ve finished welding your car frame, it’s important to make sure that all your welds meet code requirements. This means ensuring that they are structurally sound, have no gaps or weak spots, and are up to safety standards. You may need to fill in any gaps with Bondo or a weld compound before painting over them. It’s also important to sand down the frame after welding so that it has a smooth finish before painting it.

Conclusion

Welding your own car frame can be a great way to repair damage and customize your vehicle’s appearance – but it takes skill and practice to get the job done right. By following this guide, you’ll know exactly how to prepare your car frame for welding, choose the right materials for your project and make sure that all of your welds meet code requirements when you’re finished. With some patience and practice, you’ll be well on your way to creating a strong, custom car frame.